Keep it simple, back to the axis.

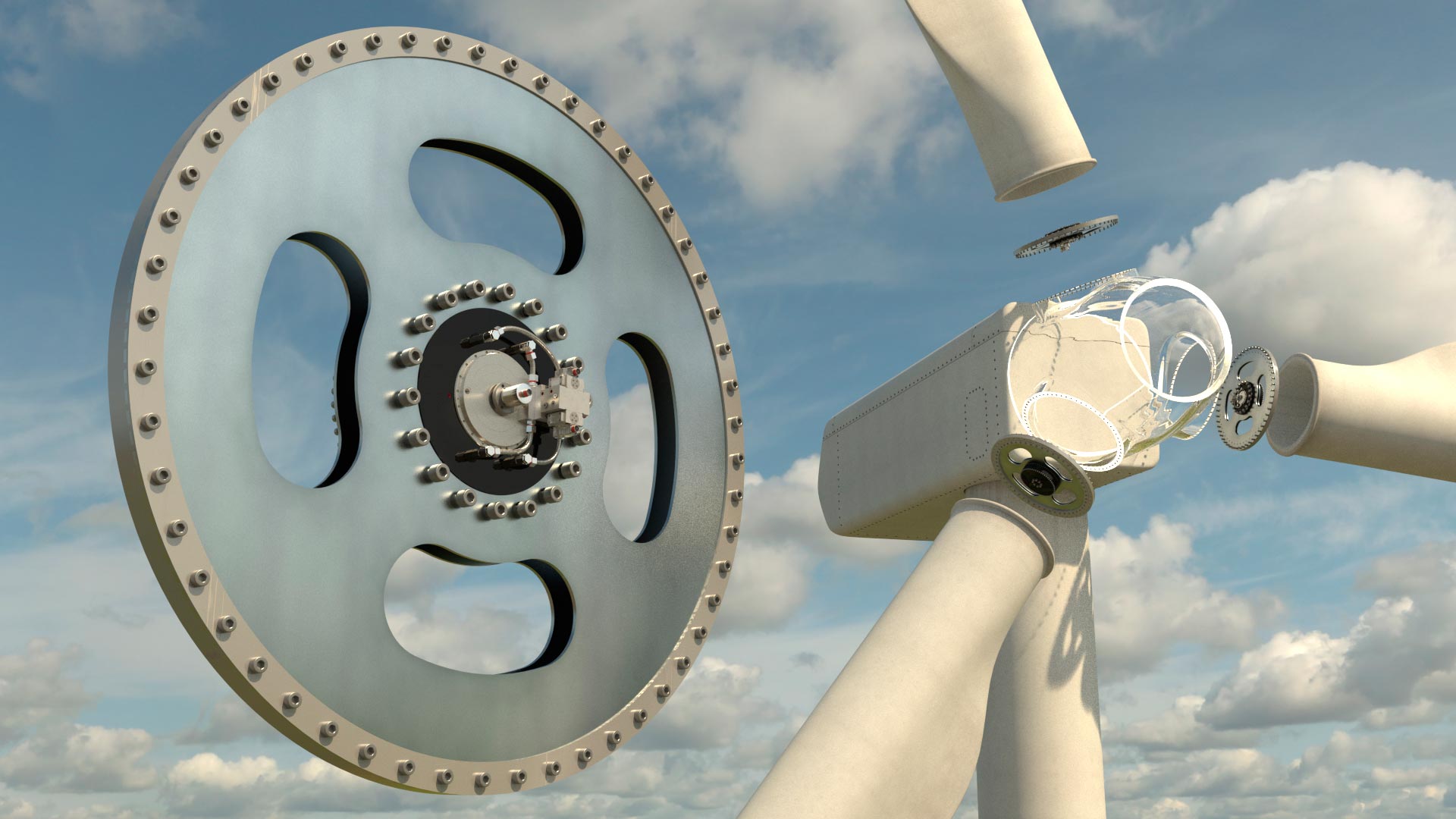

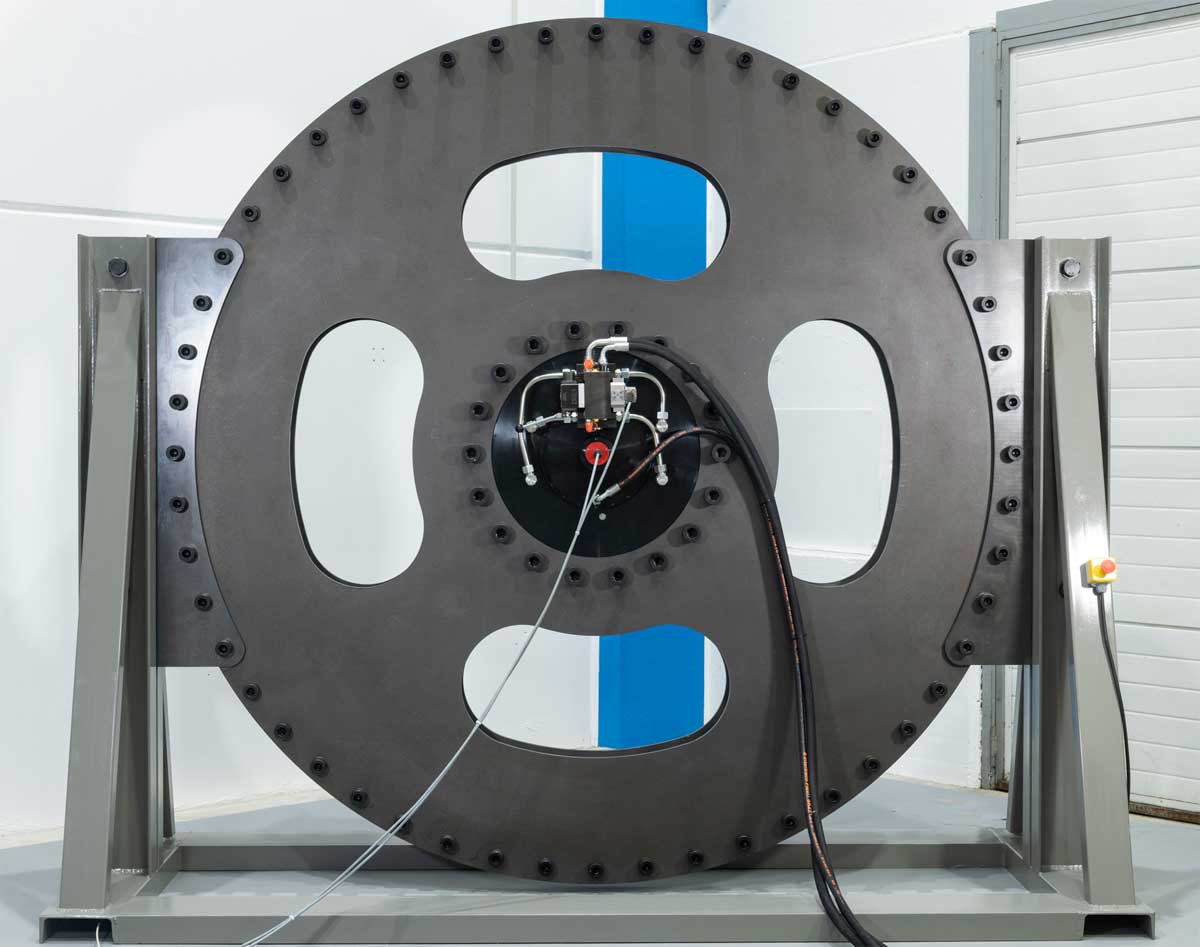

Rotak is a solution that integrates pitch control function and pitch bearings in a single flat, coaxial part.

Two functions in one product, from one supplier.

Pitch plate, bearing and hydraulic actuator.

Rotary actuator designed specifically for aeolian bearings.

The Rotak hydraulic rotary actuator is designed to generate torque while carrying out the pitch control function.

This product replaces a system currently on the market, the linear hydraulic cylinder, plus the turning and joining mechanical elements.

In one hydraulic cylinder, the hydraulic actuator creates a linear, non-rotary movement.

The force used to carry out the movement of the second axis (Fy) has a negative effect, generating radial and axial forces on the whole bearing and plate piece.

Thanks to the unique concept behind its design, the Rotak actuator can generate angular torque, meaning it moves the bearing directly with a rotary movement, coinciding with the rotary axis of the blade.

An actuator with technical improvements that improve durability, as it is centred on the axis without any watertightness or airtightness issues.

Transmission of angular momentum through angular generation.

Integrating Rotak into the windmill leads to an evolution in design and creates positive synergies with the rest of the parts.

The design and coaxial position of Rotak gives the pitch function balance and stability that leads to:

- Balance of torque and force.

- Doesn’t lead to the “zero-crossing” effect.

- More durable and fewer failures.

- Lower maintenance costs.

- Improved response time for regulating pitch.

The Rotak design generates synergies with other parts of the windmill.

- The power hoses for the Rotak actuator are hard and aren’t subjected to the pitch movement, so they don’t require maintenance.

- The pistons in the Rotak actuator aren’t exposed to the weather, so they aren’t subject to corrosion in saline or other aggressive environments.

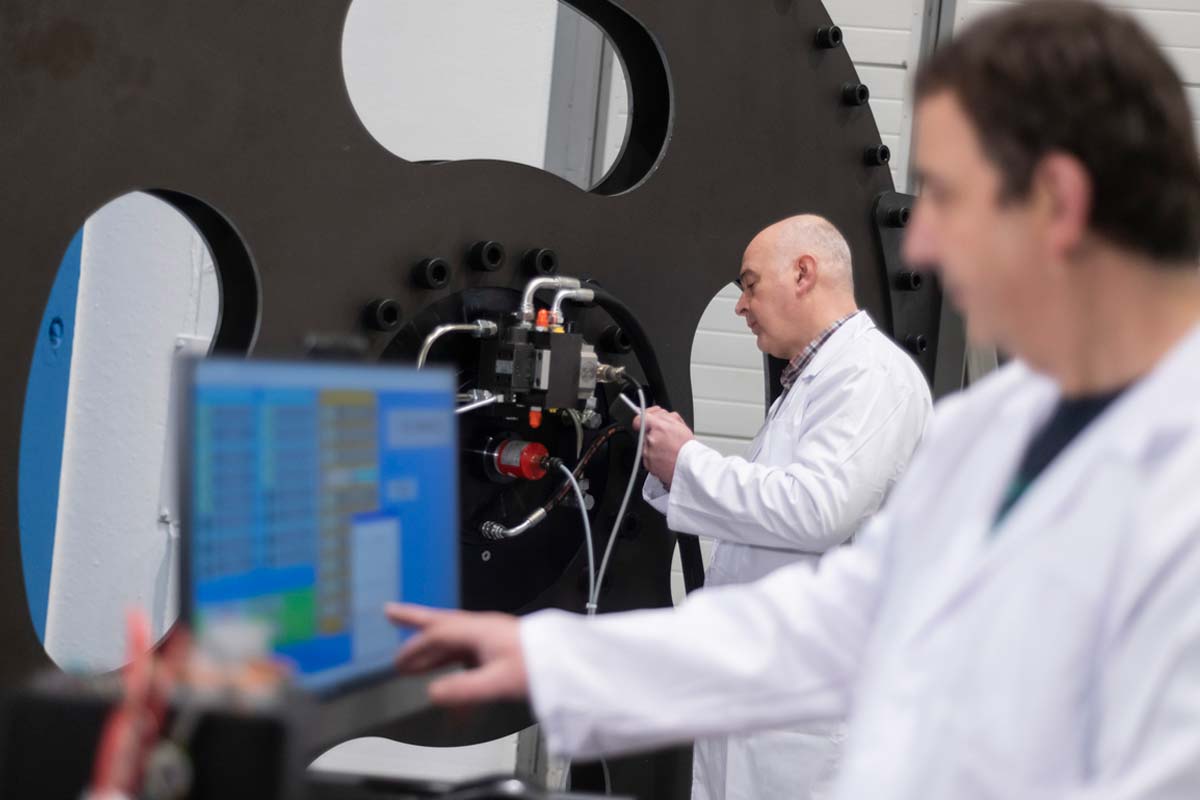

"The idea to develop an actuator with a new rotary concept was complicated, but we knew it was the way to optimise durability and prevent tension on the bearing. We’ve been working in this line for five years to ensure it is completely airtight and watertight, with guarantees for the wind sector."

Jon Gorostegi

CTO

Our patented rotary actuator system for aeolian bearings is now a reality.

Want more information on ROTAK?

We’ll be happy to get back to you with more information about this product, including availability, analysis and options.